District Energy System Inspections

Most district heating systems we inspect were installed decades ago and are poorly documented in current facility blueprints. We often find that our clients know they have issues somewhere in their system because they’re losing heat or water, but they are having a hard time finding the location of the failure because the lines are often buried 6 to 10 feet underground.

Be proactive about managing your district heating system.

“One leak can be very expensive and result in a huge loss of energy over time, EagleHawk’s data is easy to comprehend, more accurate, and offers a great user experience.”

— Frank Perry, Utilities Project Manager at Cornell University

How we can help.

EagleHawk’s expert team of FAA certified drone pilots and data analysts use drone technology to safely and efficiently inspect large installations of steam, high-temperature hot water, and condensate lines, above and below ground level. We utilize professional drones equipped with sensors, like cutting-edge thermal cameras, that can discover hidden problem areas in your district heating systems that are not apparent to the naked eye.

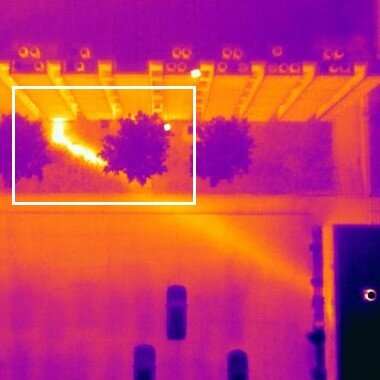

An area of concern identified from EagleHawk’s inspection service

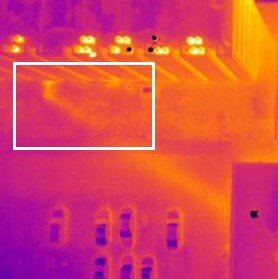

The area of concern being repaired at exact location EagleHawk identified from inspection

Area of concern fully repaired thanks to EagleHawk’s drone-enabled solutions

Once all the necessary data has been collected, our team of expert analysts will evaluate the images and supporting data to detect probable points of failure within the system. The inspection results will be compiled into a comprehensive final report that is easy to read and navigate with an interactive dashboard that includes:

the condition of each line

recommendations for follow-up maintenance

the approximate location and severity of any areas of concern

an informative picture-in-picture video of the mapped lines, including visual and thermal data

Have a question?

Proven results.

The traditional method for locating issues in a buried steam system for a private college was to dig holes until they found the source of the leak. Unfortunately, this approach was very expensive and often failed to uncover the source of the problems. EagleHawk’s inspection of the steam system allowed the college to baseline the health of the system and uncovered six “hot spots” that warranted monitoring and followup inspection. EagleHawk’s comprehensive report detailed the exact location of the suspected leaks, allowing the college’s facilities team to uncover and repair them efficiently, saving the college time and money.

EagleHawk returned to campus a few months after the initial inspection to perform a follow-up inspection on one area of concern that was repaired. The imaging and data from the second inspection verified the repairs were properly performed and the system was no longer losing water or energy.

EagleHawk helps a major university.

Part of the facilities manager’s responsibilities includes managing and maintaining the university's district heating system - a utility that provides heat and hot water to the entire campus and is crucial for the school to operate safely, efficiently and effectively, especially during the cold winter months experienced throughout Upstate New York. For years, this university hired a consultant that used a helicopter service to perform aerial inspections of the system to look for any leaks or issues. While this method worked better than traditional ground-based inspection techniques, the team felt it wasn't…